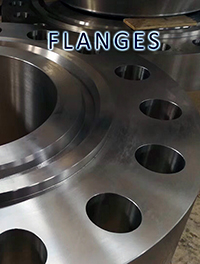

Duplex Stainless Steel ASTM/ASME SA182 F44, F45, F51, F53, F55, F60, F61

Stainless Steel ASTM/ASME SA182 F304,304L,F316,316L, F310, F317L, F321, F347

Carbon Steel ASTM/ASME A105, A350 LF1, LF2, A266, A694, A765 Gr.2

Alloy Steel ASTM/ASME SA182 F1, F5, F9, F11, F12, F22, F51, A350-LF3

Non Ferrous

Titanium ASTM/ASME SB381, Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16

Copper Nickel ASTM/ASME SB151, UNS 70600(Cu-Ni 90/10), 71500(Cu-Ni 70/30)

Brass, Al-brass ASTM/ASME SB152 UNS C10100, C10200,C10300,C10800,C12200

Nickel Alloys ASTM/ASME SB169,SB171, SB564, UNS 2200, UNS 4400, UNS 8825 UNS 6600, UNS 6601, UNS 6625

Alloy 20 ASTM/ASME SB472 UNS 8020

Hastelloy ASTM/ASME SB564, UNS10276 ( C 276 )

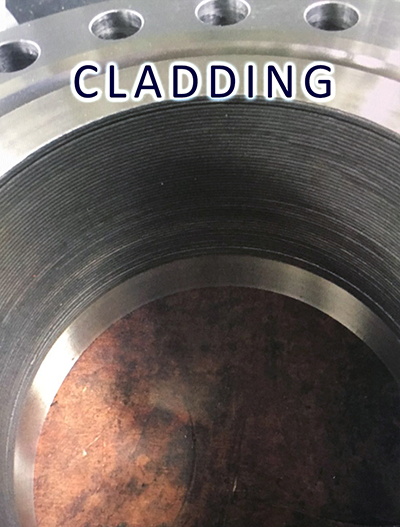

Claded materials ASTM/ASME SB898, SB263, SB264 or closer

explosion cladding, making materials of 2 in 1 or 3 in 1.

Titanium- Steel, Nickel-Steel,Titanium- Copper,

Stainless Steel- Carbon Steel, Alloys- Steel etc.